From Layout to Delivery: Mastering the Art of T-Shirt Screen Printing

The trip from layout to distribution in t-shirt screen printing encompasses a collection of crucial stages that require focus to information and critical planning. It begins with understanding the subtleties of your target market, adhered to by the choice of proper materials and the prep work of artwork that meets high requirements. Yet, as the process unravels, obstacles in high quality control and logistics can develop, potentially impacting the last outcome. Exploring these complexities discloses not just the complexities of screen printing but also the crucial methods that can elevate a brand's standing in an open market.

Understanding T-Shirt Screen Printing

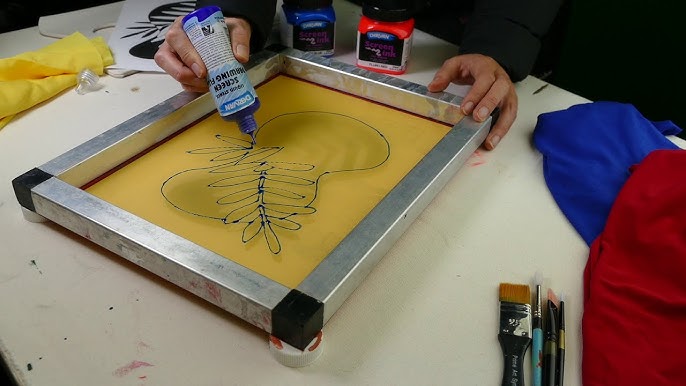

Understanding T-Shirt screen printing includes recognizing a flexible and extensively used method for moving styles onto material. This method uses a mesh and a pattern screen to use ink onto numerous textile products, mostly cotton and polyester blends. The process begins with the production of a display that includes the preferred layout, which is then carefully aligned on the material.

Ink is pressed via the screen's open locations utilizing a squeegee, enabling exact application of shade. This technique is favored for its capability to generate vibrant, durable prints that stand up well to washing and wear. In addition, screen printing can fitting both straightforward and intricate styles, making it a favored option for custom-made clothing, promotional products, and also creative jobs.

Additionally, screen printing uses scalability, making it suitable for both tiny batch orders and large-scale productions. While first setup expenses might be greater contrasted to various other printing methods, the performance and durability of screen printing often validate the investment. In general, recognizing the principles of Tee shirts screen printing is crucial for anybody wanting to take part in this prominent type of textile design, whether for business ventures or individual jobs.

Conceptualizing Your Layout

Conceptualizing your design is a crucial action in the Tees screen printing procedure, as it establishes the foundation for the whole job. This stage involves creating ideas that reverberate with your target audience while making sure that the layout straightens with the brand name's identity and message. It is important to begin by checking out themes, color pattern, and graphics that show the designated aesthetic.

Sketching preliminary ideas can be useful, allowing for a visual depiction of ideas prior to completing the layout (T-Shirt Printing). Consider making use of typography, imagery, and format in a manner that catches attention and interacts effectively. Additionally, it is vital to expect the printing strategy that will certainly be used, as this can affect layout intricacy and color choices

Engaging in conceptualizing sessions with staff member or seeking comments from possible clients can additionally improve the conceptualization process, giving diverse point of views that refine the design. Inevitably, a well-balanced style not just boosts the visual appeal of the T-shirt but additionally promotes a link with the audience, driving passion and prospective sales. Devoting time to conceive your layout can lead to an effective screen printing end result.

Picking the Right Products

When picking the best materials for T-shirt screen printing, it is necessary to take into account the material's appearance, weight, and structure, as these variables substantially influence the final product's high quality and really feel. Cotton is a preferred choice as a result of its softness, capability, and breathability to take in ink effectively, making it suitable for dynamic prints - T-Shirt Printing. Blends, such as cotton-polyester, deal resilience and wrinkle resistance, however might impact ink adherence, needing mindful consideration of printing methods

The weight of the fabric, normally gauged in grams per square meter (GSM), affects the drape and general feel of the T-shirt. Larger fabrics might supply a more exceptional appearance, while lighter alternatives are comfortable for sportswear. Appearance also plays a role; smoother textiles tend to yield sharper prints, while distinctive surface areas can develop special visual impacts.

Furthermore, think about the ecological influence of products. Organic cotton and recycled polyester are gaining popularity amongst eco-conscious consumers. Ultimately, selecting the appropriate products entails stabilizing visual appeal, capability, and sustainability, guaranteeing that the Tees not only looks excellent yet likewise fulfills the expectations of your target market.

Preparing Artwork for Printing

Preparing artwork for T-shirt screen printing requires cautious interest to information to ensure that the last print accurately mirrors the desired layout. The initial step is to produce a high-resolution digital file, ideally in vector layout, as this enables scalability without loss of top quality. Typical software program used for this purpose consists of Adobe Illustrator and CorelDRAW.

Think about the dimensions of the print location and keep correct margins to prevent style cutoff. It's additionally a good idea to include enrollment marks for alignment during the printing process. Lastly, request a proof from the printer to envision the end product before mass manufacturing. This step is necessary for recognizing any type of potential problems, guaranteeing that the printed Tee shirts fulfills the wanted top quality and design specifications. Correct prep work of artwork considerably influences the total success of the screen printing task.

Grasping the Printing Process

Next, choosing the appropriate ink is essential. Various ink kinds, such as plastisol or water-based, offer visit this web-site various finishes and longevity. Comprehending the material structure of the T-shirt likewise assists in choosing suitable inks.

Managing the squeegee stress and angle is crucial when it comes to the real printing. Consistent pressure will certainly produce also ink distribution, while the angle influences the flow and coverage. In addition, changing the speed of the printing machine can impact the ink's healing process, which is essential for assuring durability.

Quality Control and Finishing

After the printing procedure is full, carrying out effective top quality control procedures becomes vital to verify that each Tees fulfills the preferred requirements. Quality control includes a methodical method to inspecting each garment for defects, verifying that the print quality, shade accuracy, and textile honesty align with the specifications set during the style phase.

The very first step in quality assurance is a complete aesthetic inspection. This entails monitoring for usual issues such as imbalance, ink spots, or fading. Any Tees that does not satisfy the quality benchmarks need to be addressed promptly, either with reprinting or repair work.

In enhancement to visual checks, it is very important to carry out laundry examinations on an example of printed t shirts to examine the sturdiness of the inks and the general durability of the layout. These examinations aid confirm that the print will certainly maintain its vibrancy and integrity after several cleans, an important variable for customer satisfaction.

Completing touches, such as thread cutting and the application of care tags, likewise play a substantial role in quality assurance. By concentrating on these facets, companies can enhance the total discussion of their items, eventually causing an extra rewarding customer experience.

Product Packaging and Delivery Solutions

Reliable product packaging and distribution options are crucial elements of the Tees screen printing procedure, as they ensure that garments get here at their location in immaculate condition. Correct product packaging not just protects the published styles yet also boosts the unboxing experience for clients, enhancing brand identification and professionalism and reliability.

To achieve ideal product packaging, take into consideration making use of eco-friendly materials that align with sustainability fads, such as recyclable poly bags or eco-friendly boxes. Each Tees should be neatly folded up and placed in safety covering to stop creasing and potential damage during transportation. Consisting of a branded insert or care instructions can better individualize the experience, cultivating customer loyalty.

When it pertains to shipment, choosing a reputable delivery partner is vital. Assess alternatives based upon monitoring, speed, and expense capacities. Offering multiple shipping techniques can provide to different consumer requirements, from typical to expedited delivery.

Regularly Asked Concerns

What Are the Typical Errors Beginners Make in Screen Printing?

Usual errors beginners make in screen printing consist of improper screen prep work, poor ink mixing, inaccurate direct exposure times, not enough curing, and ignoring to evaluate prints. These errors can cause low quality and unsuitable lead to final items.

How Can I Stop Ink From Bleeding During Printing?

To stop ink blood loss throughout printing, warranty proper screen tension, use appropriate emulsion thickness, select the appropriate ink consistency, maintain perfect healing temperature levels, and stay clear of straining the screen with excessive ink throughout application.

What Kinds of Inks Are Finest for Different Fabrics?

Selecting inks based on textile type is necessary. Water-based inks are excellent for cotton, providing gentleness. Plastisol inks fit artificial fabrics, supplying toughness (Abilene T-Shirt Screen Printing Company). Discharge inks efficiently blend with all-natural fibers, making sure vibrant shades without endangering textile stability

Just how Do I Choose the Right Screen Mesh Matter?

Choosing the best screen mesh count relies on the desired print information and ink type. Higher mesh matters yield better details, while reduced counts assist in thicker inks. Analyze fabric type and layout intricacy for excellent results.

Can I Use Screen Printing for Little Set Orders?

Yes, screen printing can be efficiently utilized for little set orders. Abilene T-Shirt Screen Printing Company. This technique enables thorough designs and top notch results, making it a practical alternative for customized garments, promotional products, or minimal edition runs

Comprehending T-Shirt screen printing involves recognizing a versatile and extensively made use of method for transferring styles onto textile. While initial setup costs may be greater contrasted to other printing approaches, the effectiveness and toughness of screen printing frequently warrant the financial investment. Preparing artwork for Tee shirts screen printing requires careful focus to information to ensure that the last print properly mirrors the desired style. Understanding the printing process is essential for achieving top notch outcomes in Tee shirts screen printing. Typical mistakes beginners make in screen printing include improper screen preparation, insufficient ink mixing, wrong direct exposure times, not enough treating, and disregarding to test prints.